The Ultimate Guide To Sheroz Earthworks

Table of ContentsSee This Report on Sheroz Earthworks10 Easy Facts About Sheroz Earthworks DescribedSome Known Questions About Sheroz Earthworks.Things about Sheroz EarthworksAn Unbiased View of Sheroz Earthworks

For any type of earthwork contractor, it is crucial to execute deal with high quality, precision, and on time. Making use of machine control in job makers allows enhancing the different phases in the earthwork procedure, from planning to the upkeep phase - fj dynamics auto steering kit price. The machine control system aids the equipment operator in achieving the target airplane quickly and quickly

The equipment control system overviews the operator with centimeter precision. Remote support saves time and cash, as it minimizes downtime in jobsites.

Facts About Sheroz Earthworks Uncovered

Our system's components are meticulously designed to endure the harsh conditions of construction websites. Contrast of the same project executed utilizing equipment control versus the standard approach reveals that, on standard, the conventional method needs 50% even more time to accomplish the exact same job as the technology-assisted technique.

Sounds good? Get in the Xsite equipment control system; it's here to give you with a substantial benefit when dealing with earthmoving machinery. Discover just how Xsite Machine Control can boost your performance and guarantee job safety! We recognize that learning a brand-new technology could seem like a drag, but don't fret! Our friendly and professional regional assistance solutions have actually obtained you covered, ensuring that you can keep functioning smarter without interruptions while at work! With remote assistance, your neighborhood Xsite dealership can offer advice or troubleshooting without needing to go to the website! What sort of excavators does machine control fit? Xsite Equipment Control systems can be installed to any type of excavator from mini excavators to huge mining excavators.

How does machine control job? In 2D systems, the maker is furnished with calibrated inclination sensing units. These sensing units are placed on the pre-determined components of the device in excavators the sensor are generally mounted to the framework, boom (or booms), digger arm and to the quick coupler - topcon. By making use of the data received from these sensing units the system can determine the precise position of the excavators pail pointer in importance to a referral factor.

The system is extremely easy to learn the fundamentals can be shown in under one hour of training. With Xsite you do not have to fret about finding out all the tips and method at once. Added training and instructions are always readily available over remote support when needed. Get in touch with your local Xsite dealership to learn more! Just how does the remote assistance job? A cordless internet link makes it feasible to develop a remote connection in between the equipment control system and the solution facility.

Getting My Sheroz Earthworks To Work

Xsite Device Control systems support open standard documents styles, allowing smooth information flow from one system to one more. Depending on your option of system (with or without placing, i.e., 2D or 3D), your machine is equipped with inclination sensors, a controller system, and a display/operating panel.

Several hardware and software services exist to help figure out a maker's existing setting on the planet and compare it with a wanted design surfaceand construction drivers can do more to utilize the benefits. Device control is the usage of various positioning sensing units and a display to offer the driver with a recommendation in between the position of the bucket or blade and the target grade.

Depending upon the configuration, maker control systems can give the driver with a simple visual overview to pail or blade placement, or can automatically relocate the blade to grade by speaking to the equipment's hydraulics - https://www.domestika.org/en/floydoverbeck4500. There are machine control systems available for just regarding any maker: graders, dozers, excavators, dirt and asphalt compactors, scrapers, trimmers, grating devices, and pavers

The Best Guide To Sheroz Earthworks

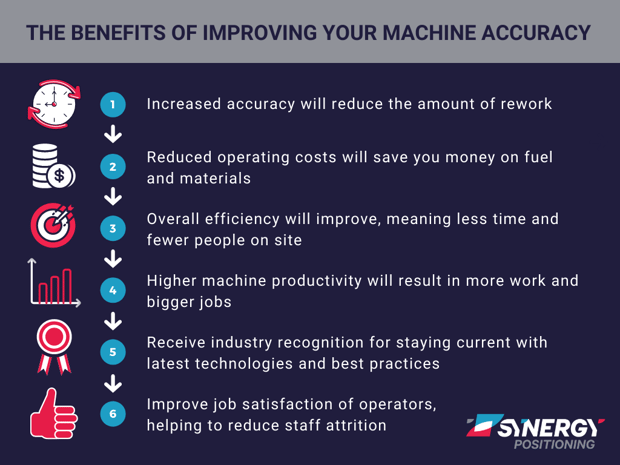

Some advantages consist of decreased rework, boosted job efficiency, and lower evaluating costs. Equipment control can also help boost productivity and minimize general prices. This innovation is transforming the method the building and construction sector functions. Building tools without equipment control will end up being a distant memory and the benefits obtained from it will certainly be countless.

Trimble maker control systems give a myriad of advantages to any individual that makes use of earthwork equipment and, at EarthCalc, we can provide you with 3D data for your maker control-enable tools. Unsure if maker control deserves the price? Think about the complying with reasons that you require to consider this alternative.

Using general practitioner lined up with your 3D layout data, these systems practically assure that you will certainly get rid of or place the proper amount of product at the construction website. On most building and construction sites, revamp is a common and frustrating reality, yet with Trimble machine control, you can eliminate the requirement for rework.

Top Guidelines Of Sheroz Earthworks

Frequently, with Trimble machine control, you can remove excess devices at a certain work website. As an example, a work that might have required the usage of 3 or 4 items of digging deep into devices currently could need just two tools to accomplish the very same job in much less time. This allows you to move he said your devices to an additional task site and take care of several tasks at one time.